Mycelium - An Underground Network That Could Save the Planet

Light weight, durable, fire-resistant and acoustic, mycelium pushes the boundaries of what furniture can be

What is Mycelium?

Mycelium, one of nature’s many marvels, hidden beneath our feet in a vast network of thread-like structures, is the linchpin of thriving ecosystems both ecologically and functionally. The vegetative part of fungi, this living material consists of a fine network of branching filaments called hyphae and is unseen but crucial to the lifecycle of visible parts of the fungi, or mushrooms, that we see.

Manufacturing with Mycelium

Its innate versatility means Mycelium is already being used as insulation and packaging for its foam-like structure, as an alternative to traditional plastics, reducing waste and environmental impact. The fungus also has huge potential to be the base of strong and lightweight construction materials, offering eco-friendly benefits to reduce the built environment’s impact on our planet.

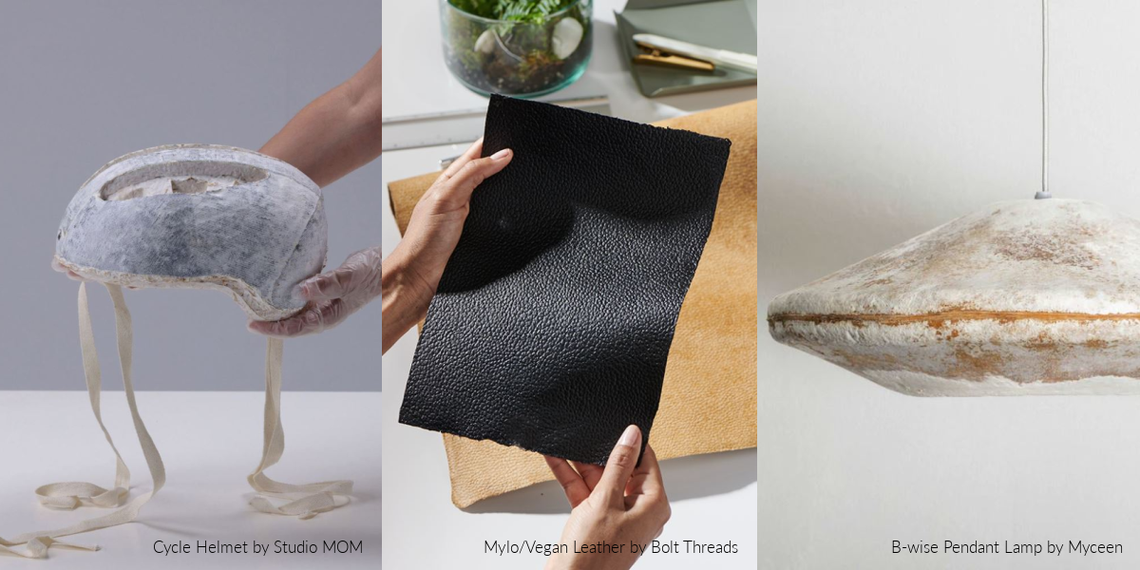

Having already made an appearance in the fashion world in the form of faux, plant-based leather (Mylo by Bolt Threads), Mycelium breaking into other industries in the form of chairs, lighting (B-wise Pendant Lamp by Myceen) and even architecture. Its unique qualities: light weight, durable, fire-resistant, water resistant, and some acoustic properties, make it highly desirable material to continue to push the boundaries of what an accepted product is, whilst being highly sustainable due to the low energy and minimal resources needed for it grow.

Moulding Mycelium – Unlocking Its Functionality

Mixed with agricultural waste, mycelium can be moulded into any shape over a few weeks, whilst needing only minimal energy input to grow. Read on to learn how this process works.

First the agricultural waste is mixed with mycelium. The mixture is set in moulds and let to grow under controlled temperature and humidity. The fungus then feeds on the agricultural waste and expands to fill out the mould, with nothing artificial needed to strengthen the shape, as the mycelium binds naturally. Once the mould has filled the material is removed and dried completely, so it doesn’t expand any further. Once the mycelium shape has been dried effectively and is dead, it is ready to use!

Our Work - From Fungi to Furniture

Over a significant number of months our research and development teams have been researching and experimenting with multiple recycled and regenerative materials including Mycelium. Following feedback from the market we registered a high interest in sustainable solutions from organisations who are striving to commit to and reach sustainability goals. For any workplace team, a sustainable environment is a challenge, as a huge 40% of all carbon emissions come from the built environment. With a long way to go but massive potential to revolutionize, it is the responsibility of us, manufacturers, and designers, to ensure we are holding out products which meet and exceed this demand.

Recently we launched our new Mycelium Panel, compatible with Palisades II and Grid, as an optimised acoustic, fire-resistant and naturally beautiful accessory for our zone divider range. Their low density, high porosity, and low thermal conductivity create a natural barrier through a network of interwoven filaments, slowing down the spread of heat and flames, as well as enabling remarkable sound absorption across a wide range of frequencies. Learn more and reach out about our new accessories here.

An experiential and destination space for architects, designers and workplace strategists looking to discover ways to c…

ARCHITECTURE & DESIGN

Spacestor believes the future of the workplace is more than just a physical space - it's an experience, a destination –…

ARCHITECTURE & DESIGN